Flange

Machined Rings

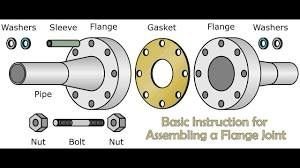

Description

A flange is a flat, circular mechanical component used to connect two or more parts, such as pipes, valves, or machinery. It typically features bolt holes around its perimeter for securing it to another flange or surface, creating a tight, leak-proof seal. Flanges come in various sizes and materials, designed to withstand pressure, temperature, and environmental factors, making them ideal for use in industries such as plumbing, oil and gas, and manufacturing.

Advantages

- Flanges offer several advantages, including providing a strong and secure connection that ensures leak-proof seals in piping and machinery systems. They also allow for easy assembly and disassembly, making maintenance and repairs more convenient. Additionally, flanges are highly versatile, available in various materials and sizes to suit different industrial applications.

When using flanges, it's important to ensure proper alignment and tightness to prevent leaks and ensure safety

Our Work Benefits

Flanges offer several benefits, including ensuring a secure, leak-proof connection between components, which is vital in maintaining system integrity. They also simplify maintenance by allowing easy d

Frontiers of Research

Research on flanges focuses on improving materials for enhanced durability, corrosion resistance, and pressure handling capabilities. Studies also explore innovative designs to improve sealing perform

FAQs

Types of Flanges: Exploring different flange types, such as weld neck, slip-on, blind, and threaded flanges, and their specific applications.

An overview of the international standards for flanges, such as ASME, ANSI, and DIN, and how they ensure compatibility across industries.

Understanding the various materials, such as stainless steel, carbon steel, and alloy metals, and how they impact flange performance and durability.

Identifying ways to reduce flange costs without sacrificing quality, including bulk purchasing and material optimization.

Inquiry

Inquiry