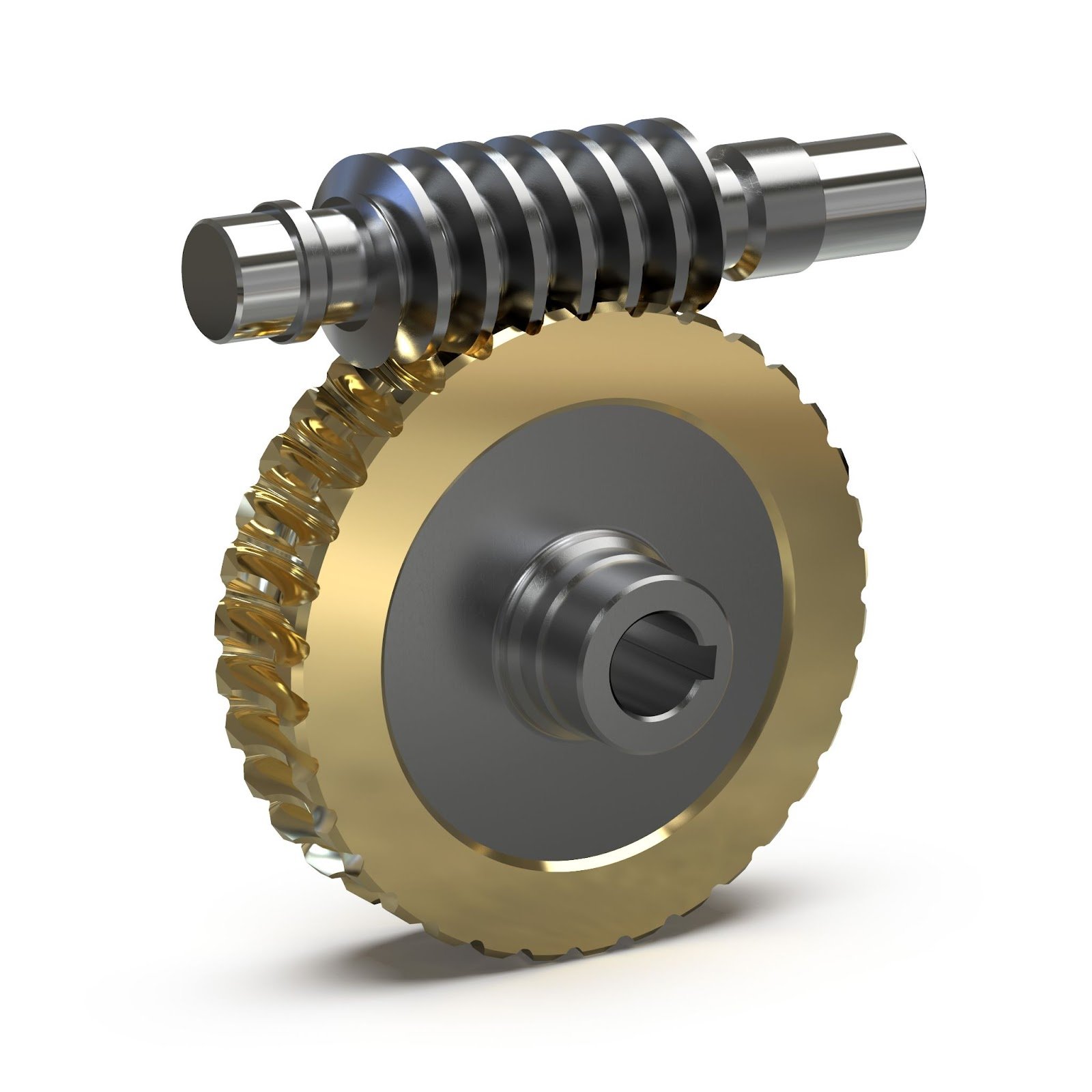

WORM GEAR

Gear Components

Description

A worm gear consists of a worm (screw-shaped gear) and a worm wheel (a toothed gear), used to transmit motion and torque between non-intersecting shafts. It offers a high reduction ratio, enabling significant speed reduction and increased torque. Worm gears are compact, self-locking, and often used in applications requiring precise movement and space efficiency.

Advantages

- Worm gears offer high torque output and significant speed reduction in a compact design. Their self-locking feature prevents backdriving, ensuring stability. Additionally, they operate smoothly and quietly, making them ideal for space-constrained and noise-sensitive applications.

Our Work Benefits

Worm gears provide efficient power transmission with high torque and speed reduction in a compact design. Their self-locking nature enhances safety by preventing reverse motion. Additionally, they ens

Frontiers of Research

Research on worm gears focuses on improving efficiency, material durability, and minimizing energy losses due to friction. Studies explore advanced materials and coatings to enhance wear resistance an

FAQs

Worm gears consist of a worm (screw-shaped gear) and a worm wheel, designed to transmit motion at right angles with high reduction ratios, providing efficient torque multiplication in a compact form.

Worm gears are often made from durable materials like bronze or steel, with surface coatings or heat treatments to enhance wear resistance, minimize friction, and extend lifespan.

Commonly used in machinery that requires high torque and precision, such as conveyors, hoists, elevators, and tuning instruments, due to their ability to handle large load capacities and space constraints

Inquiry

Inquiry